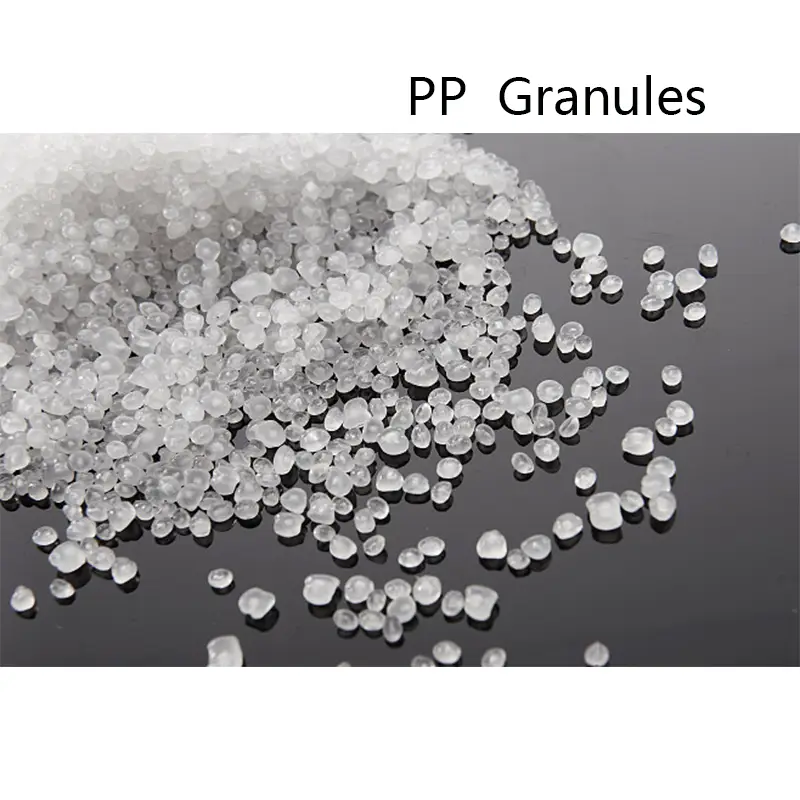

Specifications:

Polyvinyl chloride(PP) | |

Appearance | White or colorless solid product |

Odor | For details of different models, please consult sales staff |

PP content | |

Implementation Standard | |

Packing and Storage:

- Packing: Please contact our sales staff for details.

- Storage: Please contact our sales staff for details.

Description:

Polypropylene (PP) is a thermoplastic resin. Polypropylene is obtained by polymerization of propylene. It is a non-toxic, odorless, tasteless milky white, highly crystalline thermoplastic resin. It is one of the lightest varieties of all plastics currently available. It has outstanding advantages such as good formability, good surface gloss of products, heat resistance and corrosion resistance.

Usage:

1. Plastic products: Polypropylene particles are widely used in food packaging, medical equipment, electrical and electronic equipment, automotive parts and other fields. The plastic products made are usually characterized by high strength, good rigidity and high transparency, such as food boxes, household items, pipes, sinks, etc.

2. Fiber products: Polypropylene particles are also used to make fiber products. The fibers made are soft, wear-resistant, antistatic, waterproof, oil-proof, and pollution-resistant. They can be widely used in waterproof clothing, medical products, filter materials, etc.

3. Auto parts: Polypropylene particles are used to make parts such as car bumpers, body panels and driving lamp covers due to their excellent toughness and impact resistance.

4. Electrical and electronic products: Polypropylene particles can also be used in the manufacture of electrical and electronic products, such as the insulation layer of wires and cables, the shell of smart phones, and the bracket of electronic products.

Medical devices: Polypropylene particles can also be used to make various medical devices, such as medical supplies, syringes, infusion bags, etc. These products have excellent antibacterial, corrosion and scratch resistance.